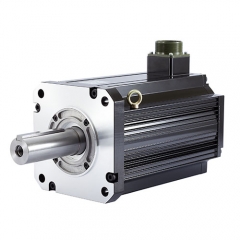

Servo Motor

(Also known as Servo Drive Motor / Motion Control Motor)

A Servo Motor is a precisely controlled electric motor designed to provide accurate position, speed, and torque control through feedback from a sensor such as an encoder or resolver. Unlike standard motors that rotate when powered, servo motors work as part of a closed-loop control system — where a servo drive (controller) continuously monitors the actual position or speed and adjusts the motor current in real time to match the command signal. Servo motors are essential for industrial automation, robotics, CNC machines, packaging, and motion control systems that require high accuracy, responsiveness, and repeatability.

Working Principle

Command Signal: The controller sends a target position, speed, or torque command to the servo drive.

Motor Operation: The servo drive supplies power to the servo motor, which converts electrical energy into mechanical rotation.

Feedback Loop: The motor’s encoder measures actual position or speed and sends feedback to the drive.

Error Correction: The servo drive compares actual vs. commanded values and instantly corrects any deviation by adjusting the motor current.

Closed-Loop Control: This constant feedback enables precise, stable control even under load changes or external disturbances.

Main Types of Servo Motors

| Type | Description | Typical Use |

|---|---|---|

| AC Servo Motor | Uses AC power, high efficiency, and smooth motion | Industrial automation, robotics |

| DC Servo Motor | Uses DC power, simpler control, good for small systems | Portable or low-voltage equipment |

| Brushless Servo Motor (BLDC) | Uses electronic communication, has a high lifespan, and low noise | Modern servo systems and robotics |

| Brushed Servo Motor | Uses carbon brushes for commutation, simple but less durable | Educational or low-cost systems |

| Linear Servo Motor | Converts electric power directly into linear motion | CNC cutting, precision positioning |

Key Features

Closed-loop feedback control: Ensures accurate motion and torque regulation.

High positioning accuracy: Error margin typically within microns or arc-minutes.

Fast dynamic response: Quick acceleration and deceleration for high-speed automation.

High torque density: Compact size with strong torque output.

Low noise and vibration: Smooth operation under varying load conditions.

Programmable control: Fully compatible with servo drives, PLCs, and motion controllers.

Servo Motor Inertia Classifications

| Inertia Type | Description | Typical Application |

|---|---|---|

| Low Inertia | Light rotor, fast acceleration/deceleration | Pick & place, robotics, light axes |

| Medium Inertia | Balanced rotor for moderate load | Conveyors, indexing tables |

| High Inertia | Heavy rotor for stable heavy-load control | Machine tools, rotary tables, presses |

Applications

Robotics and Automation Systems – precise multi-axis control.

CNC Machine Tools – accurate cutting, milling, and positioning.

Packaging and Labeling Machines – synchronized, repeatable motion.

Printing and Textile Machines – speed and tension control.

Pick & Place Equipment – rapid positioning and response.

Factory Automation and Conveyors – smooth and stable operation.

Advantages

Extremely precise motion and positioning control.

Maintains stability under variable load conditions.

High energy efficiency and long operational life.

Compact design suitable for integrated systems.

Enables modern IIoT (Industrial Internet of Things) connectivity when paired with smart drives.

Typical Integration Example

Servo Motor connects to ZIPPGEAR Precision Reducer → delivers mechanical power to a robotic or automation axis.

Smart Servo Drive (with encoder feedback and torque monitoring) connects upstream to PLC.