TSA Series Servo Motor

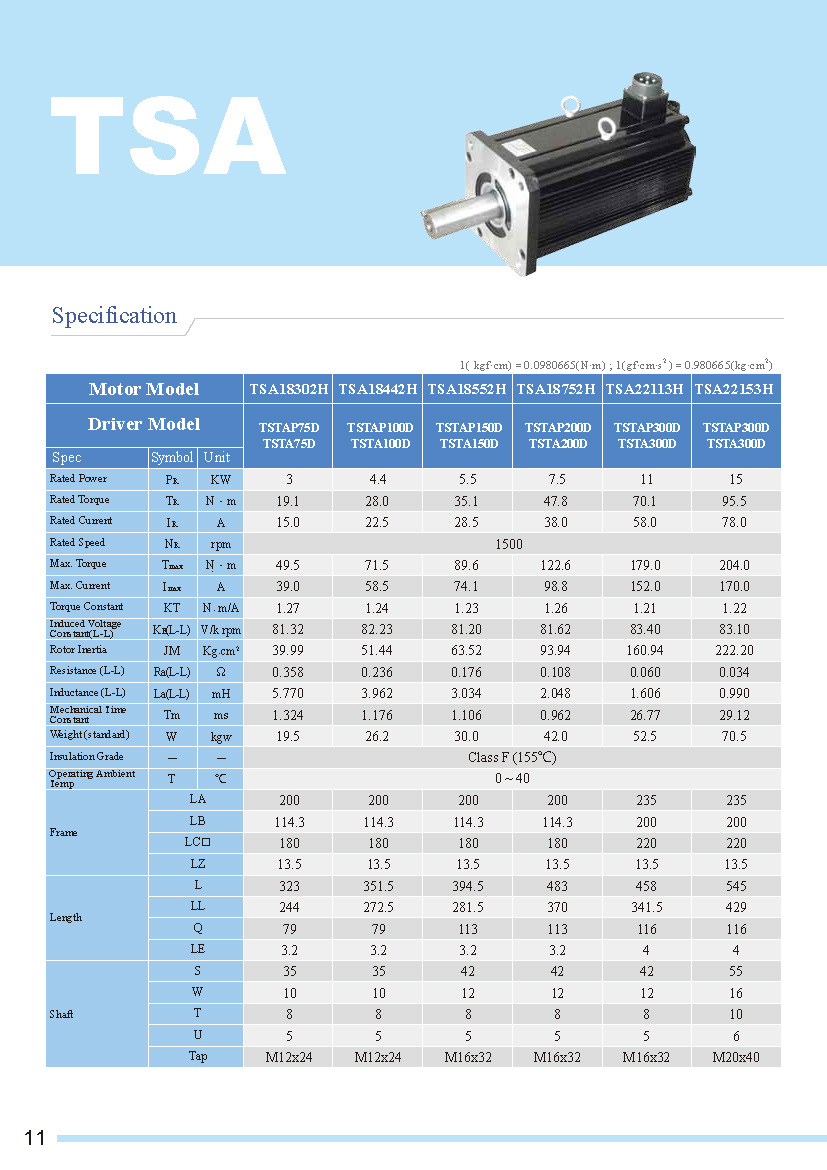

TSA Series covers a wide power range (from a few kilowatts to 15 kW or more) and is intended for industrial servo applications that require high torque and reliable motion control.

Key Features

Closed-loop servo system compatibility: Designed to work with servo drives and feedback devices (encoder/resolver) for precise position, speed, and torque control.

High torque/high power: The series offers substantial torque and power.

Industrial-grade construction: The motors have a robust mechanical design suitable for demanding automation environments.

Wide range of sizes and ratings: The TSA Series provides flexibility across different machine/power requirements.

Standard mounting and integration: Likely conforms to standard servo-motor mounting flanges and shafts, enabling easier integration into machine design.

Common Applications

Machine tools and CNC machines (spindles, axes)

Packaging, printing, and converting machinery

Automation lines where heavy-duty axes or high torque motion is required

Conveyors, indexing tables, or rotary units where servo-driven motion is needed

Retrofitting or upgrading automation systems that require higher servo power

Design & Selection Considerations

Match the motor to the drive: Ensure the servo drive is compatible with the TSA Series motor (voltage, current, feedback, and tuning).

Torque & speed requirements: Select a model in the TSA Series whose torque rating at the required speed meets your mechanical load.

Inertia matching: When using servo motors, matching rotor inertia to load inertia is essential for motion stability and dynamic response.

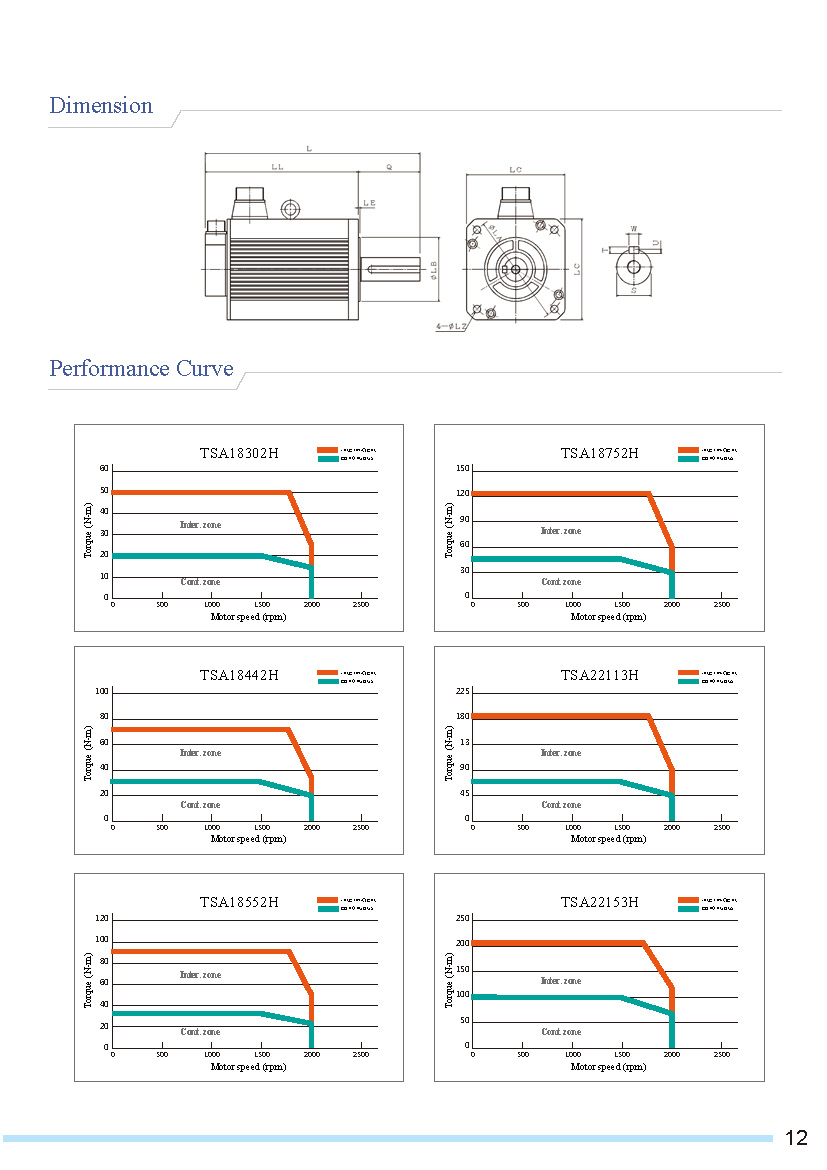

Mounting & environment: Consider the installation space, cooling, environmental conditions (temperature, dust), and motor housing.

System integration: Integration with the motion control system (PLC, servo drive, feedback wiring) must be planned; cable routing, EMC, and maintenance access must be considered.