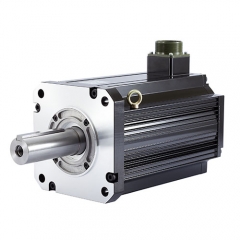

High-Inertia Servo Motor

The High Inertia Series servo motors are designed for applications where the driven load has substantial inertia (e.g., large rotors, heavy gear trains, indexing tables, or machine tools with substantial mass). With higher rotor inertia, these motors are optimized for smooth, controlled motion of heavy loads—where ultra-high acceleration is less critical than stability and torque.

Key Features

High Rotor Inertia: The motor’s rotating mass is deliberately higher, helping to match heavy-load inertia and dampen oscillations or resonance in the system.

Robust Torque Capability: Built to deliver continuous and peak torque suitable for heavy-duty axes with large mass.

Stable Motion Profiles: Suited for axes where high acceleration isn’t needed, but smooth, stable motion and heavy-duty operation are required.

Feedback & Control Ready: Typically supports high-resolution encoders or resolvers for precise positioning despite the heavy load.

Industrial Mounting Compatibility: Built to standard servo motor mounting and shaft dimensions for integration with machinery.

Applications

Indexing tables, turn-tables, or rotary platforms carrying significant masses.

Heavy printing presses, machine tools with large work-stocks, or automation systems driving heavy loads.

Conveyor drives, die-casting machines, or machinery where the load inertia dominates system dynamics.

Systems where precise positioning under load is required and where the motion profile is moderate in terms of acceleration.

Advantages & Considerations

Better load matching: A high-inertia motor means the rotor inertia is closer to the driven load inertia, improving control stability and reducing overshoot or hunting.

Improved system robustness: Heavy load drives often benefit from the inherent damping of the higher-inertia motor.

Cost-effective for heavy loads: Instead of using a low-inertia, high-speed motor and oversized gear train, this series provides a more direct approach.

Reduced motion bandwidth: Because inertia is higher, acceleration/deceleration will be slower compared to low-inertia motors. For applications requiring rapid starts/stops or high-bandwidth response, a low-inertia motor would be more appropriate.

Typical Specification Range

Power ratings: In the example listing from TECO, ~0.3 kW to 0.75 kW for specific frame sizes.

Rotor inertia values: Higher than those of typical servo motors designed for high dynamics (specific values depend on frame size).

Designed for moderate speed/torque axes rather than ultra-high-speed rapid motion axes.

Design/Selection Tips

Match the inertia: Choose a motor whose inertia is comparable to or slightly higher than the load inertia to ensure stability.

Check torque reserve: For heavy loads, confirm that the continuous and peak torque ratings suit your axis requirements.

Speed and duty cycle: Ensure the speed rating and duty cycle align with your application; heavy-inertia motors might not suit high-speed recurring starts.

Feedback & tuning: Use high-resolution encoders and properly tuned servos, as heavy inertia can reduce responsiveness.

Cooling and mounting: Ensure proper cooling and mounting provisions—heavy inertia and large loads may lead to higher thermal stress.

High inertia Series Servo motor