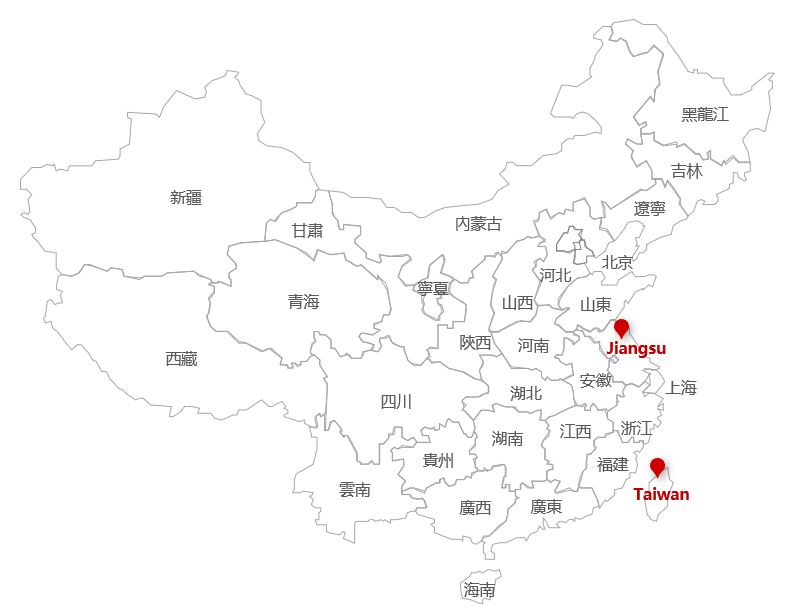

ZIPP GEAR is an ISO 9001-certified manufacturer based in Taiwan with over 30 years of expertise in producing high-precision gears and machined parts. Our advanced production capabilities enable us to manufacture a wide range of gear types, including spur gears, helical gears, and spiral bevel gears, meeting the exacting standards of global industries.

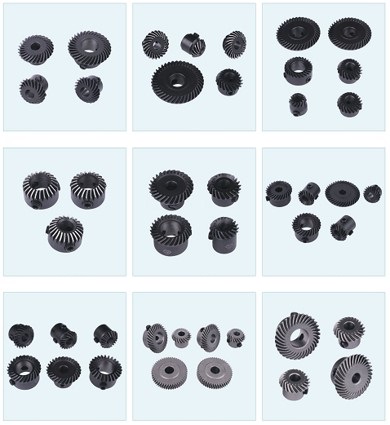

Gear Types and Applications

Spur Gears: Ideal for high-load, low-speed applications with minimal axial thrust, ZIPP GEAR produces spur gears with high dimensional accuracy and fine surface finish to ensure efficient power transmission.

Helical Gears: Designed for smoother, quieter operation under higher loads and speeds, our helical gears are manufactured with precise helix angles and controlled tooth geometry for optimized performance.

Spiral Bevel Gears: Used in applications requiring smooth torque transmission at right angles (e.g., automotive differentials, machine tools), we produce spiral bevel gears with precise tooth engagement for reduced noise and vibration.

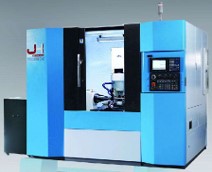

Manufacturing Techniques

To ensure superior gear quality, performance, and durability, ZIPP GEAR employs a range of advanced manufacturing processes, including:

CNC Machining: High-precision CNC lathes and milling centers are utilized for gear blank preparation and the profiling of complex gear teeth.

Gear Hobbing & Shaping: We utilize high-speed hobbing and shaping machines to produce straight and helical teeth with precise tolerances.

Gear Grinding: For gears requiring high accuracy and surface finish (DIN 6 and better), precision grinding is performed on dedicated gear grinding machines.

Lapping & Honing: Applied to improve tooth contact patterns and reduce noise in high-performance gears.

Heat Treatment: Processes such as carburizing, induction hardening, and nitriding are used to enhance gear hardness and wear resistance.

Quality Assurance: Each gear is inspected using CMMs, gear measuring centers, and surface testers to verify tolerances, tooth geometry, and finish.

Customization & Engineering Support

ZIPP GEAR offers custom gear design services and engineering support to help clients select the optimal materials, heat treatment processes, and gear profiles that meet their specific application needs.

With a focus on precision, reliability, and innovation, ZIPP GEAR is your trusted partner for high-quality gearing solutions across a wide range of industries.