DST 56 Series Stepper Motor

(Hybrid stepping motor, frame size ~56 mm, with connector-type wiring)

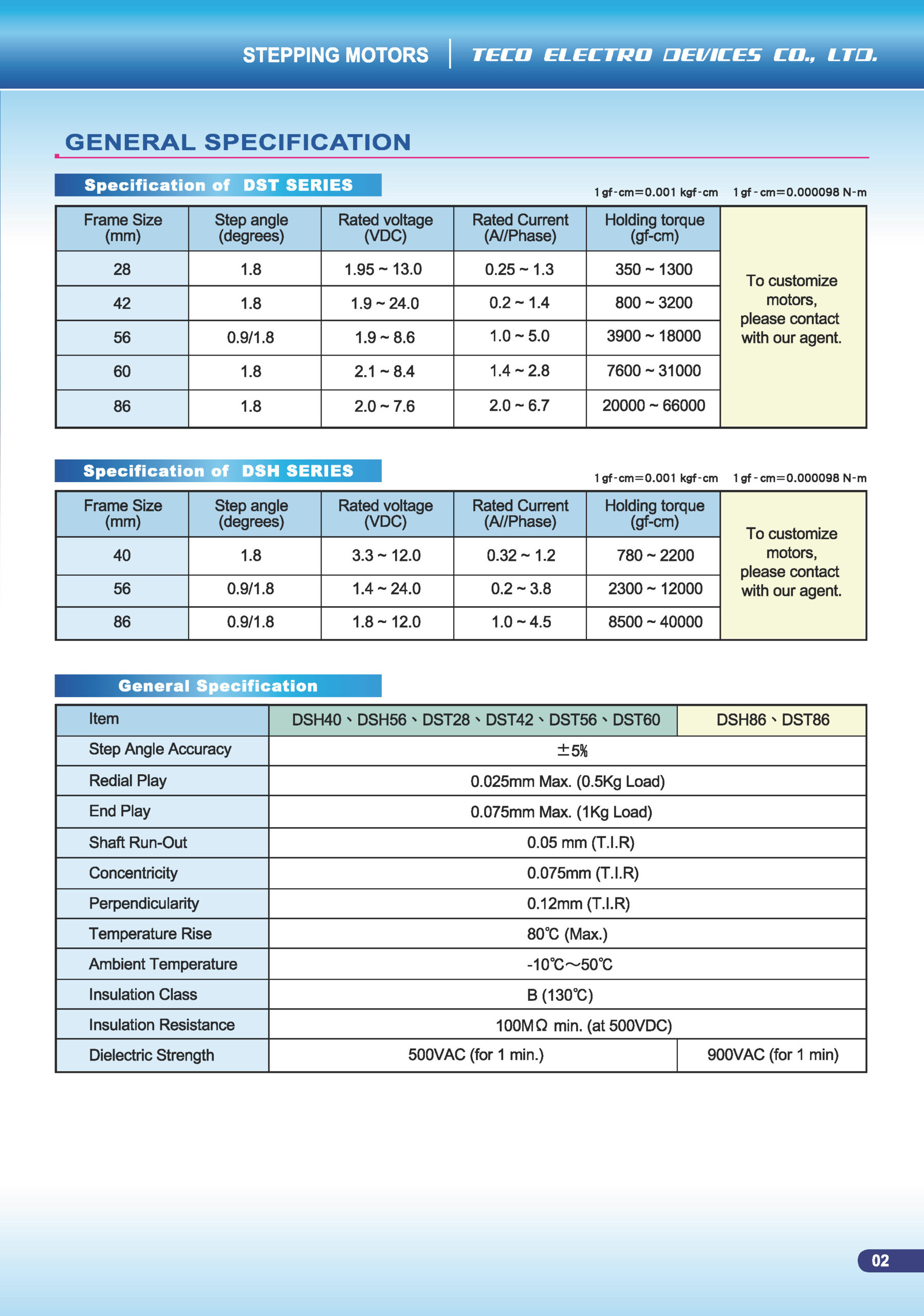

The “DST 56” series is part of TECO’s DST family of hybrid stepping motors — the “56” denotes the approximate frame size class (~56 mm).

The Connector Series designation implies that the motor features a factory-fitted plug/connector interface (rather than solely flying leads), simplifying wiring, installation, and maintenance.

These motors are designed for moderate-torque, precise position applications where incremental motion is required but full servo-level dynamics may not be necessary.

Key Features & Specifications

Frame Size ~56 mm: A larger size than the smaller series (DST42), but still compact enough for many automation axes.

Stepper Motor Construction: As a hybrid stepper motor, it provides fixed-step-angle motion (common variants include 1.8° per step) and is suitable for open-loop or, optionally, closed-loop stepping systems.

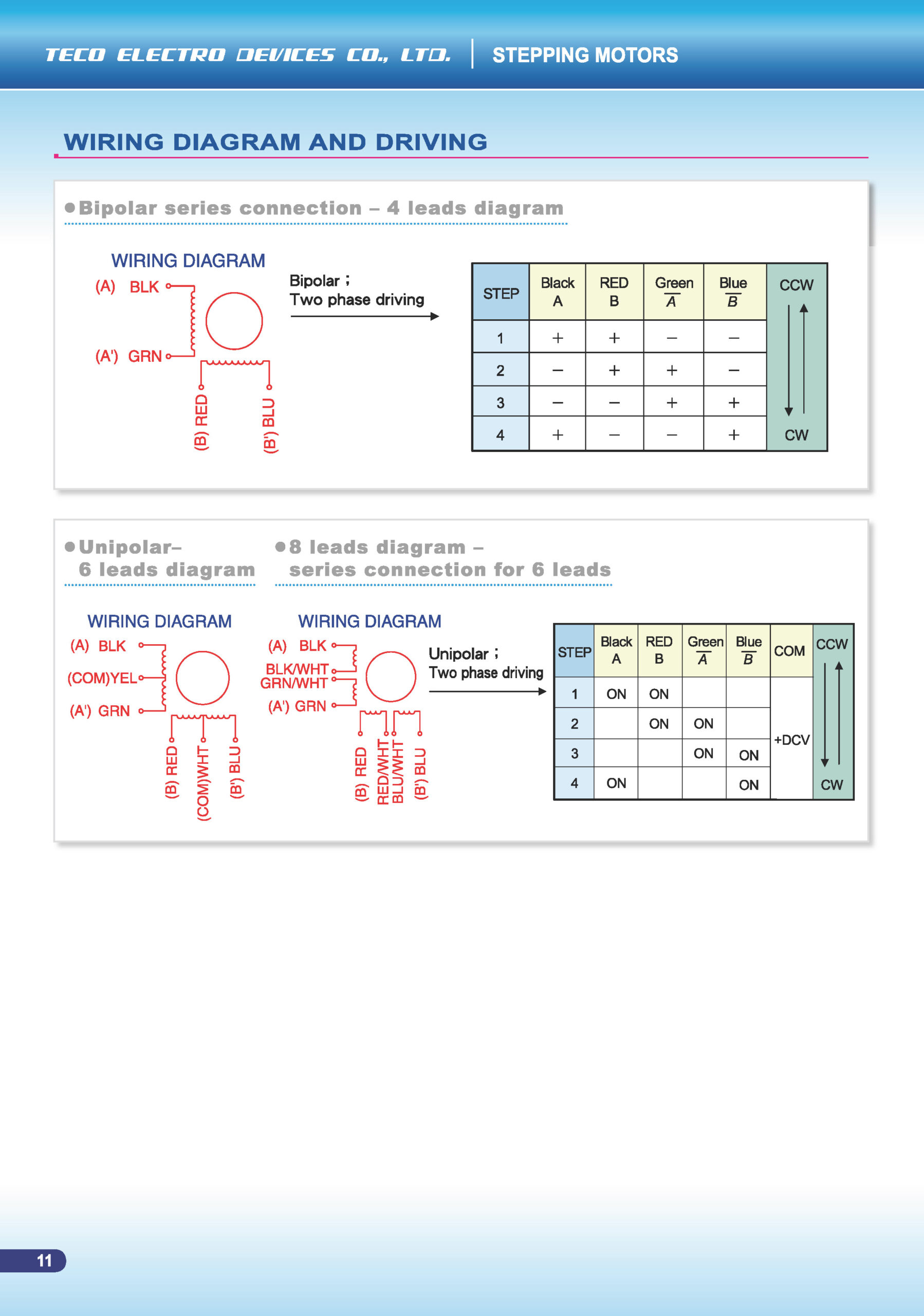

Wiring Options:

Bipolar wiring (4 leads)

Unipolar wiring (6 leads or 8 leads), depending on the variant. The DST56 catalogue shows different lead configurations.

Connector Interface: Designed for plug-in use, which helps reduce installation time and wiring errors in modular systems.

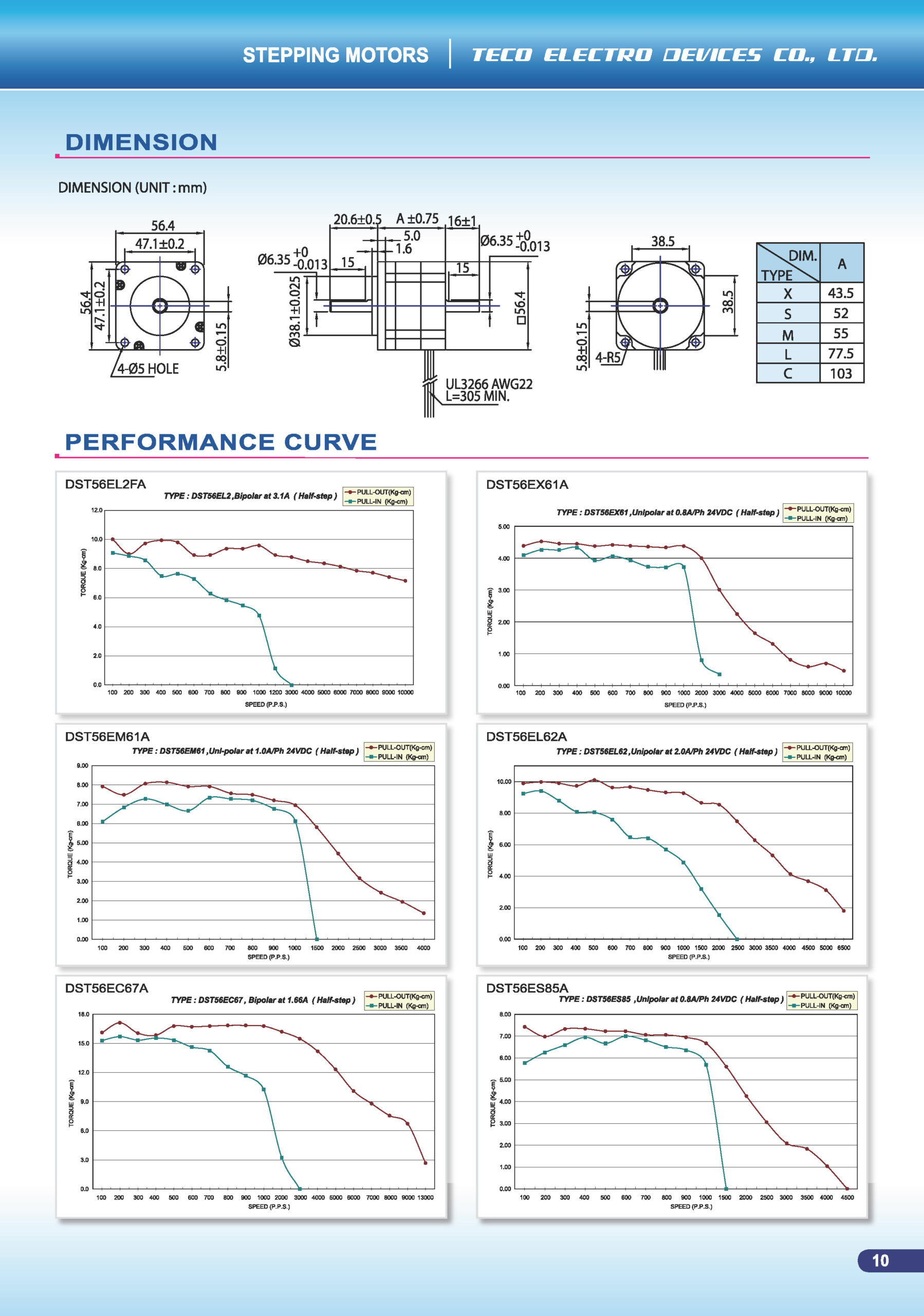

Technical Data Present in Catalogue: The TECO stepping motor catalogue lists the DST56 series, including winding resistance/inductance, torque vs. speed curves, dimensions, and wiring instructions.

Applications

Medium-torque automation axes such as indexing tables, rotary feeders, conveyor drives, or machine peripherals in packaging, assembly, or light manufacturing.

Applications where a compact yet higher-torque stepping motor is required and open-loop stepping control is sufficient (i.e., without the complexity or cost of a servo).

Systems where the connector interface provides the benefits of modular installation and more straightforward wiring harness integration.

Design & Selection Considerations

Torque vs Speed: As with all stepping motors, torque decreases with increasing speed. Designers should review the DST56’s torque-vs-speed (pull-out/pull-in) curves in the specification sheet.

Load Inertia Matching: The motor’s rotor inertia should be suitably matched to the load inertia to avoid loss of steps or resonance — frame 56 implies a moderate inertia class.

Driver Compatibility: Use a stepper driver compatible with the motor’s wiring configuration (4-lead vs 6/8-lead), voltage rating, and current rating. The connector type implies a specific cable/plug layout.

Control Strategy: While open-loop stepping is common, if you require higher speed, higher precision, or feedback correction, many controllers and closed-loop stepper variants are available.

Mechanical Integration: Ensure correct mounting, coupling, shaft dimension, cooling, and alignment. A ~56 mm frame motor implies more torque and possibly greater heat output than smaller frames — thermal management may be relevant.

The DST 56 Series Stepper Motor from TECO offers a compact yet robust stepping motor solution for moderate-torque positioning axes. Its connector interface simplifies integration, and its frame size allows more power than smaller stepper classes. When properly matched with load, driver, and system design, it is a cost-effective choice for many automation systems.