DST 42 Series Stepper Motor

The DST 42 series is part of TECO’s DST family of hybrid stepping motors, where “42” indicates a frame size class around 42 mm.

The Connector Series designation means that this motor line offers a standard connector interface (plug-in) rather than just loose lead wires, facilitating easier wiring and system integration.

These motors are designed for compact motion-control applications that require precise incremental positioning but may not demand full servo-motor performance.

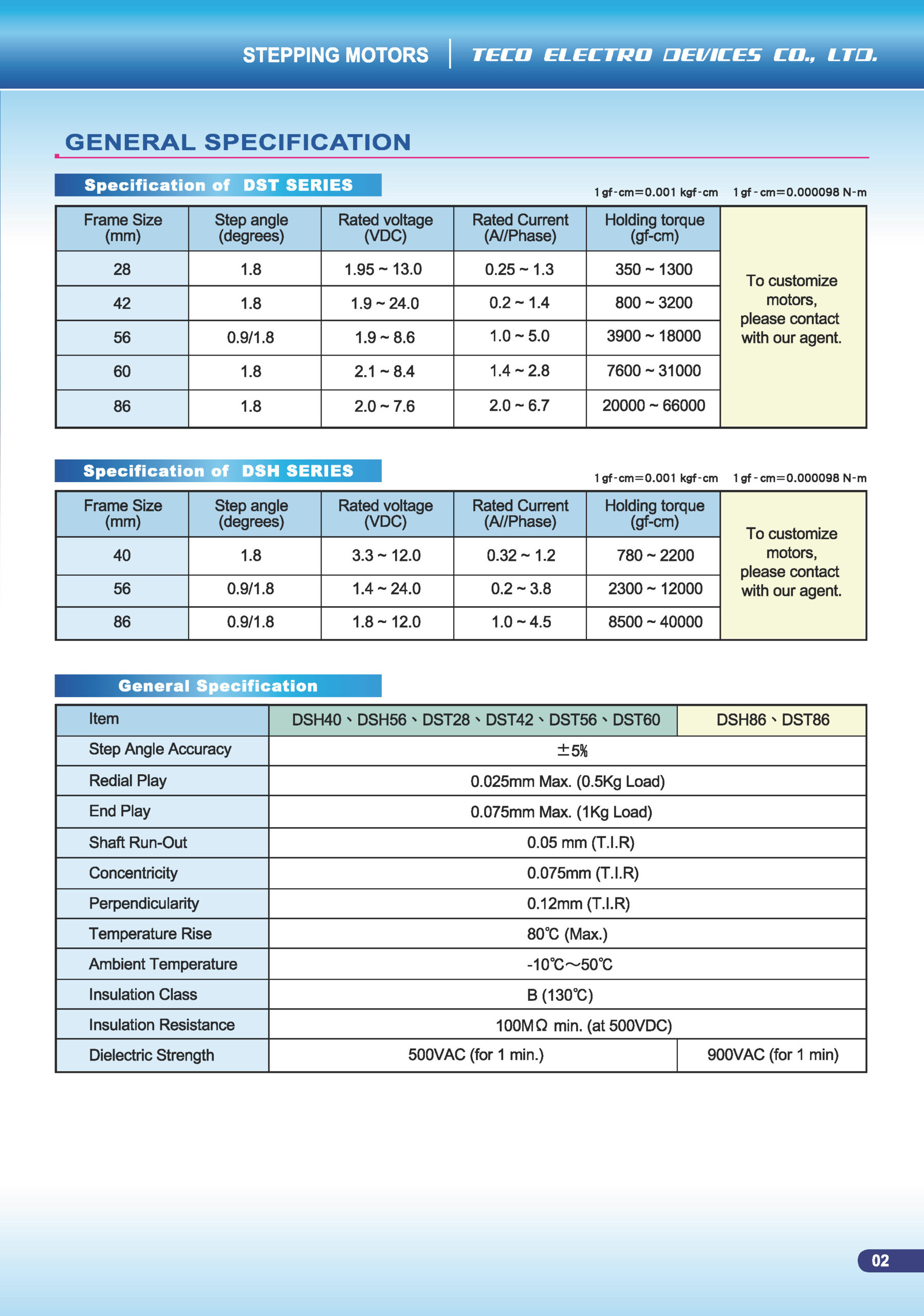

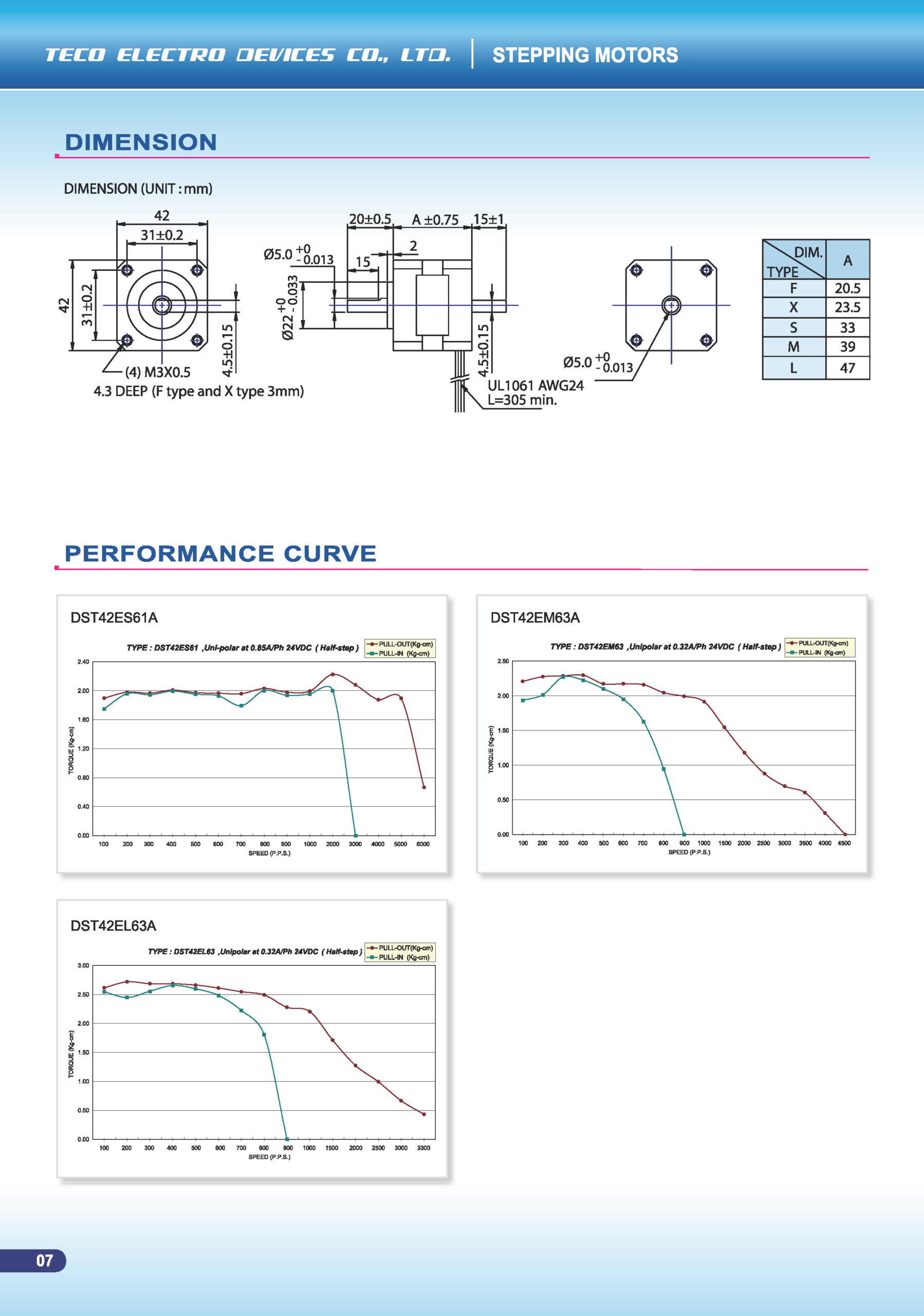

Key Features & Specifications

Frame Size ~ 42 mm: Situated between smaller frame motors (e.g., DST28) and larger frame ones (e.g., DST56).

Stepper Motor Type: Hybrid construction typical of two-phase stepping motors; step angle for many models is 1.8° (i.e., 200 steps per revolution) though specifics depend on variant.

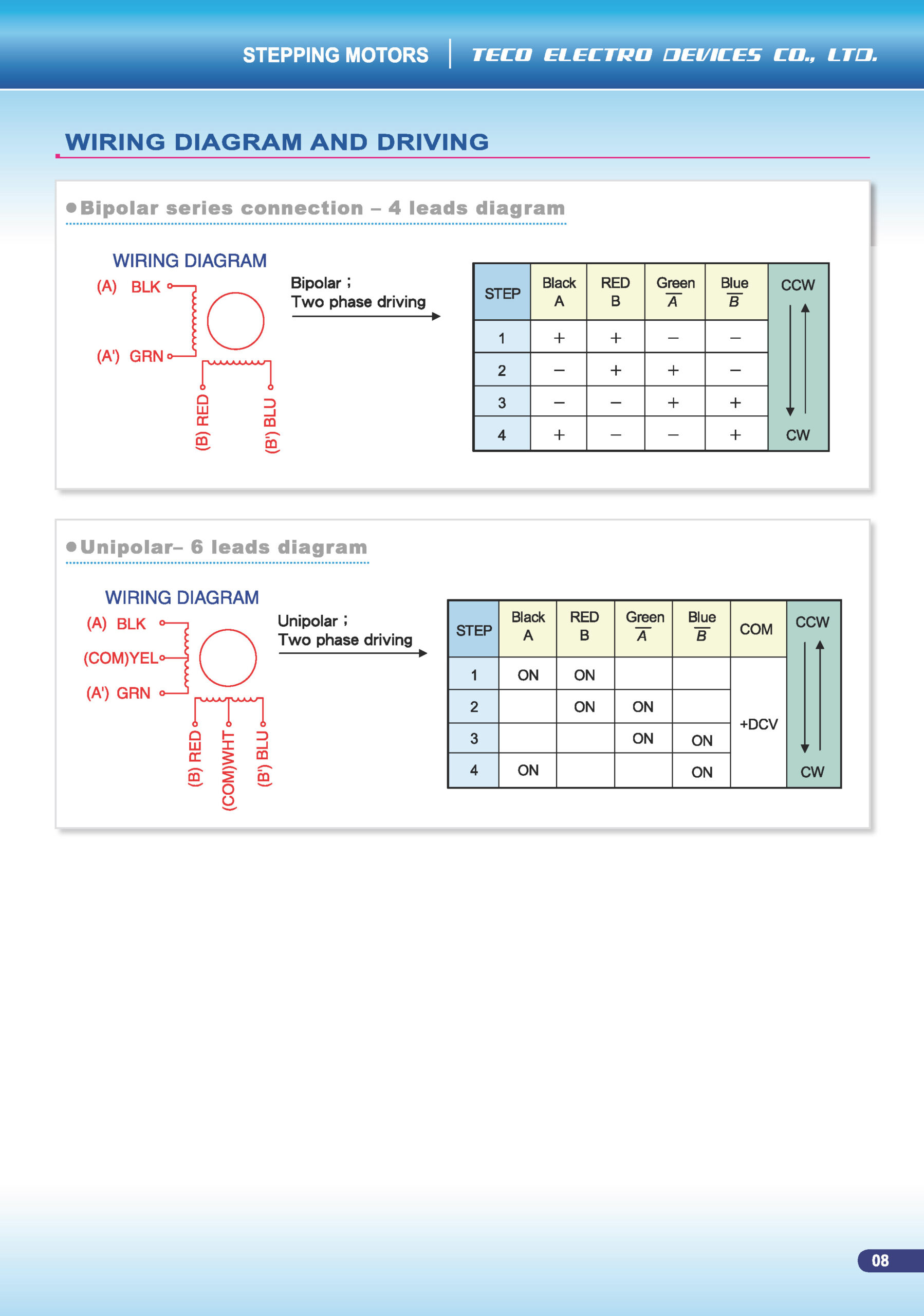

Wiring Options:

Bipolar connection (4-lead)

Unipolar connection (6-lead)

The datasheet mentions these options for the DST42 series.

Connector Interface: The “Connector Series” implies factory-fitted plugs or sockets for wiring, simplifying installation and maintenance in automation modules.

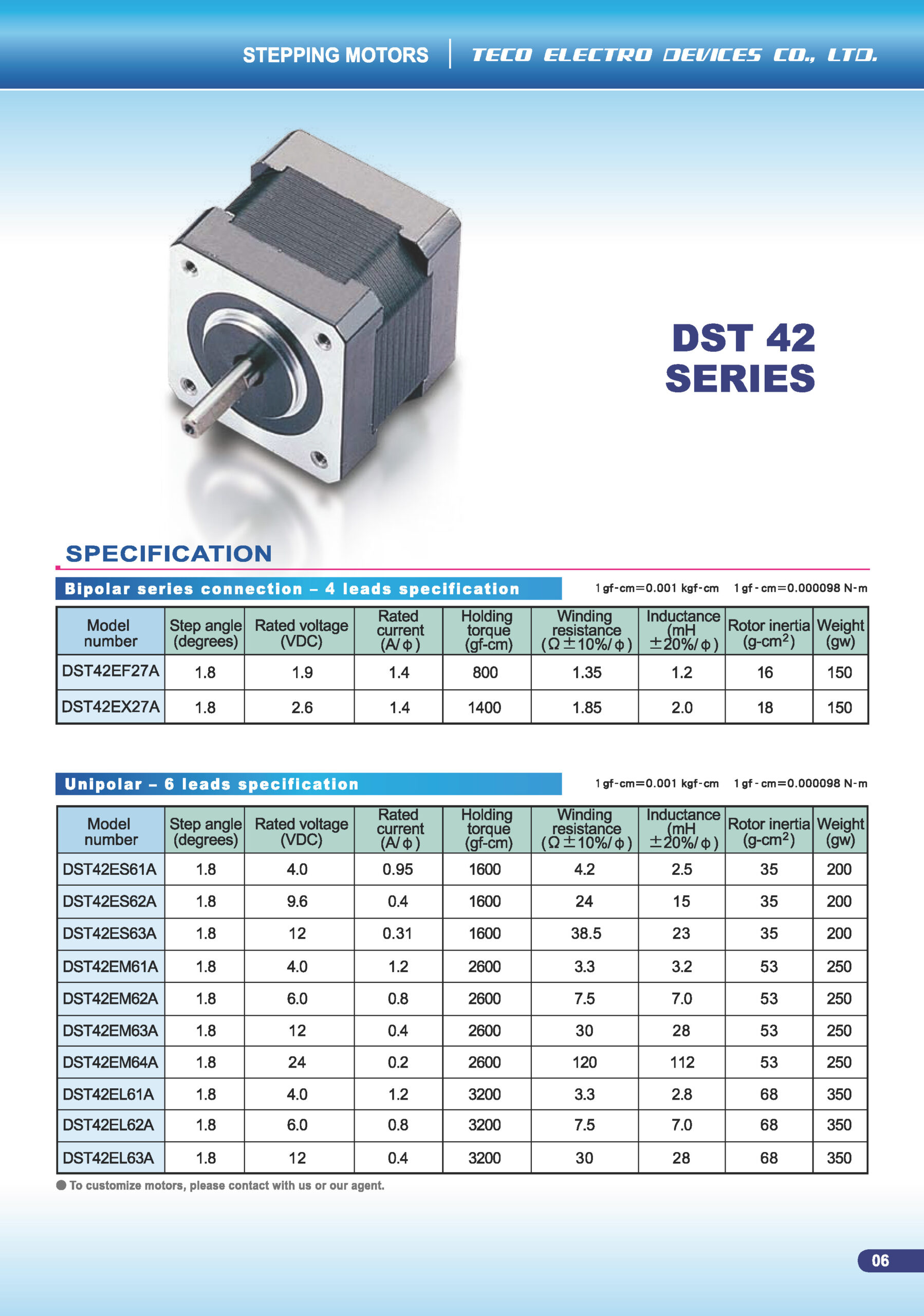

Performance Data Available: The official TECO stepping motor catalogue includes dimensions, winding resistance/inductance, wiring diagrams, performance curves, and specifications for the DST42 series.

Applications

Compact automation axes, such as feeders, small indexing tables, or rotary modules, for packaging, light assembly, or machine tooling.

Systems that require accurate incremental motion but do not require ultra-high dynamic performance (as with high-end servos).

Situations where wiring simplicity and modular integration are beneficial, thanks to the connector interface.

Selection & Design Considerations

Torque vs Speed: As with all stepper motors, available torque declines at higher speeds. Designers should review the specific model’s torque vs. speed (pull-out/pull-in) curves from the datasheet.

Inertia Matching: Ensure load inertia is correctly matched to the motor’s rotor inertia; excessive load inertia or frequent, rapid direction changes can cause lost steps or resonance.

Driver Compatibility: Choose a stepper driver compatible with the motor’s wiring style (4-lead vs 6-lead) and current/voltage rating. The connector version requires proper plug/cable matching.

Control Strategy: While open-loop operation is standard for steppers, if high speed, accuracy, or load disturbances occur, consider either micro-stepping or a closed-loop variant.

Mechanical Integration: With a 42 mm class frame, ensure mounting space, shaft coupling, cooling, and wire routing are all properly handled to support reliable operation.

The DST 42 Series Stepper Motor by TECO is a compact, cost-effective hybrid stepping motor solution for moderate-motion axes that require precise stepping control and simplified wiring/integration, thanks to its connector interface. When well-matched to the application (load inertia, speed, torque, and driver), it delivers robust positioning performance without the complexity or cost of a complete servo system.