DSH86 Series Stepper Motor

The DSH86 Series is part of TECO’s DSH family of hybrid stepping motors.

The “86” denotes an approximate frame size of 86 mm, signifying a larger frame motor designed for higher torque and heavier load applications.

These motors are engineered for automation axes that require precise incremental motion (step-by-step control) with moderate to heavy loads, while maintaining the simplicity of stepping motors.

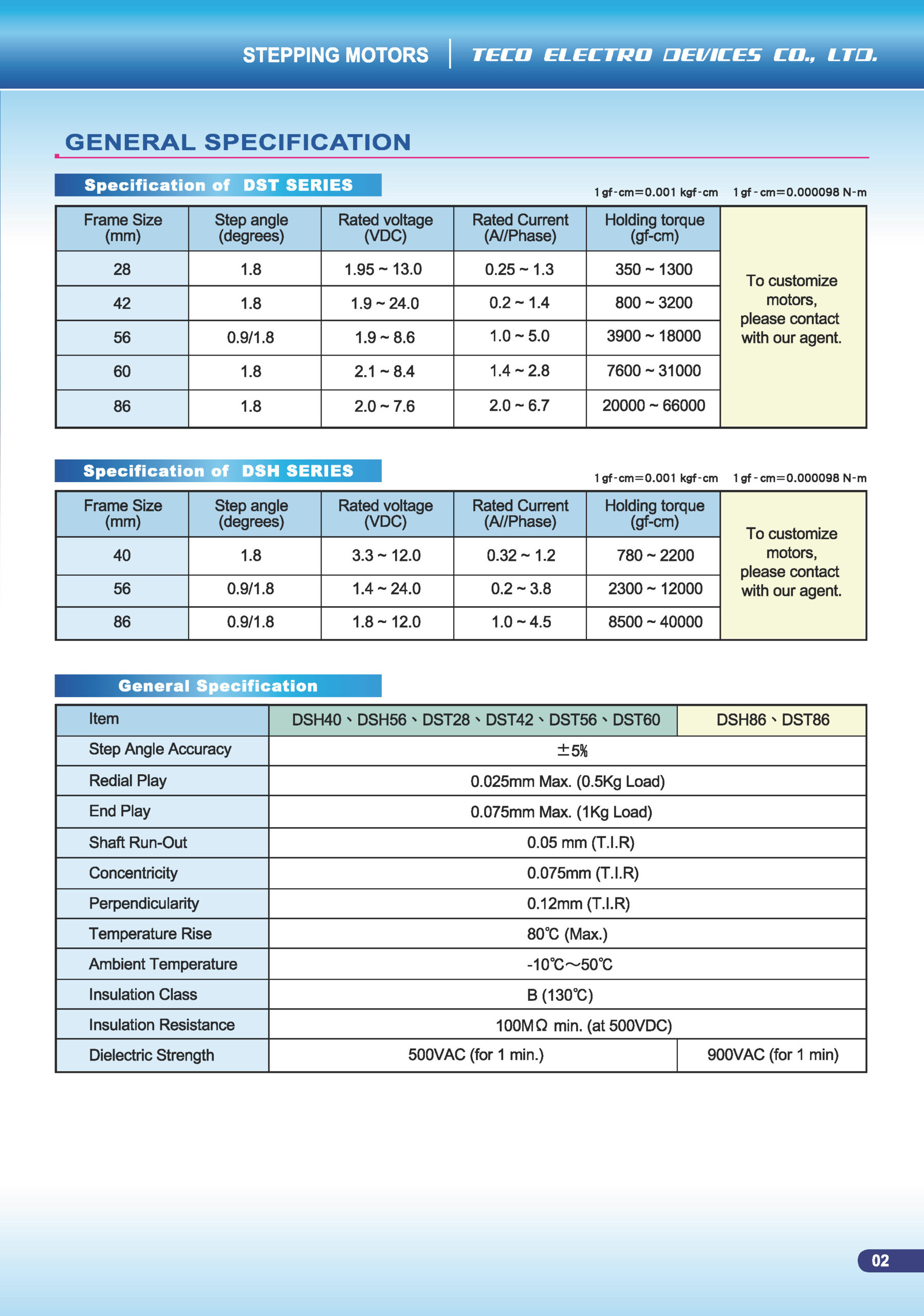

Key Features & Specifications

Frame size ≈ 86 mm: Appropriate for moderate-torque applications.

Hybrid stepping construction: As with other series, it uses a multi-phase winding and toothed rotor design for accurate incremental motion.

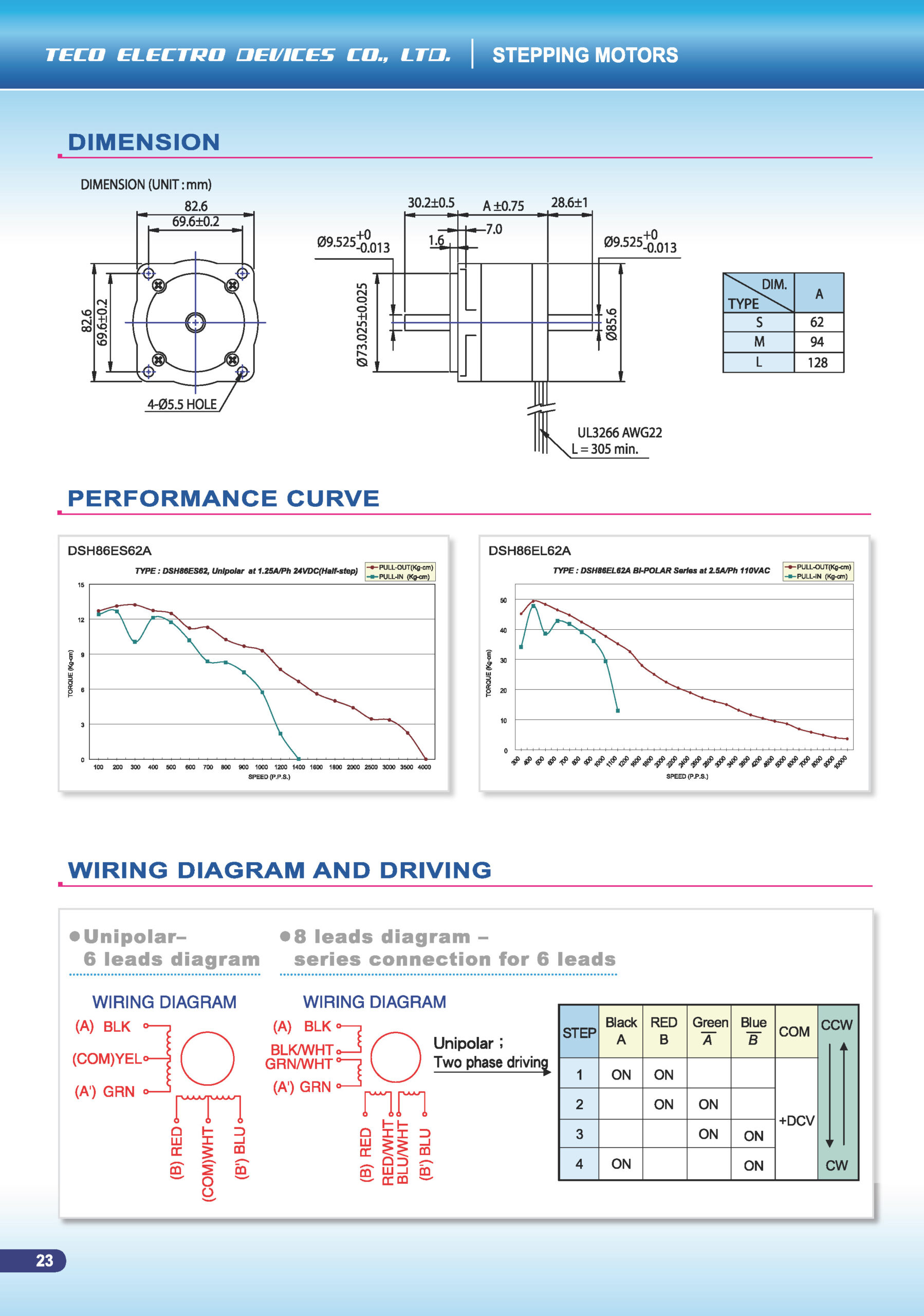

Typical step angle: Commonly 1.8° per complete step (200 steps/rev) as is standard in many hybrid steppers, although you should verify the exact variant in the catalogue.

Winding/lead variations: The catalogue lists 6-lead and 8-lead wiring diagrams for DSH86 models.

Performance data available: Specs such as holding torque, rotor inertia, resistance/inductance, and dimensioning are listed in the manufacturer’s documentation.

Typical Applications

Rotary indexing tables or turntables with heavier payloads are used in packaging, assembly, or manufacturing machinery.

Motion axes in automation where a stepping motor is sufficient (open-loop or lightly closed-loop), but the torque demand exceeds what smaller-frame steppers can handle.

Mid-to-heavy duty feeders, conveyors, or modules requiring precise stops/starts and incremental positioning without the cost/complexity of a complete servo motor.

Design & Selection Considerations

Load inertia matching: Ensure the driven load’s inertia is within limits relative to the motor’s rotor inertia to avoid lost steps or oscillation. The larger frame (86) gives more tolerance, but still must be matched.

Torque vs speed trade-off: As with all stepper motors, available torque declines at higher speeds. Consult the specific DSH86 torque-vs-speed curve from its datasheet.

Driver compatibility: Ensure the stepper driver supports the winding style (6-lead/8-lead) and the current/voltage specifications of the chosen DSH86 variant.

Control mode: Many stepper motors use open-loop control; if high precision, variable loads, or speed changes are involved, consider whether a closed-loop stepper or servo might be more appropriate.

Mechanical integration: With a larger frame size, ensure the proper mounting footprint, cooling/venting (if required), shaft coupling, cable routing, and space allowances are addressed.

The DSH86 Series Stepper Motor from TECO offers a larger-frame, higher-torque stepping solution ideal for automation applications where stepping (incremental) motion is acceptable and full servo performance isn’t needed. When properly matched to load, driver, and system requirements, it delivers reliable, cost-effective positioning for heavier-duty axes.