DSH40 Series Stepper Motor

The DSH40 Series is a hybrid stepper motor line from TECO with a frame size of ~40 mm (“40” in the series name) designed for compact motion‐control applications. It’s intended for applications where precise incremental (step-by-step) motion is required and where cost or simplicity are more important than complete servo motors.

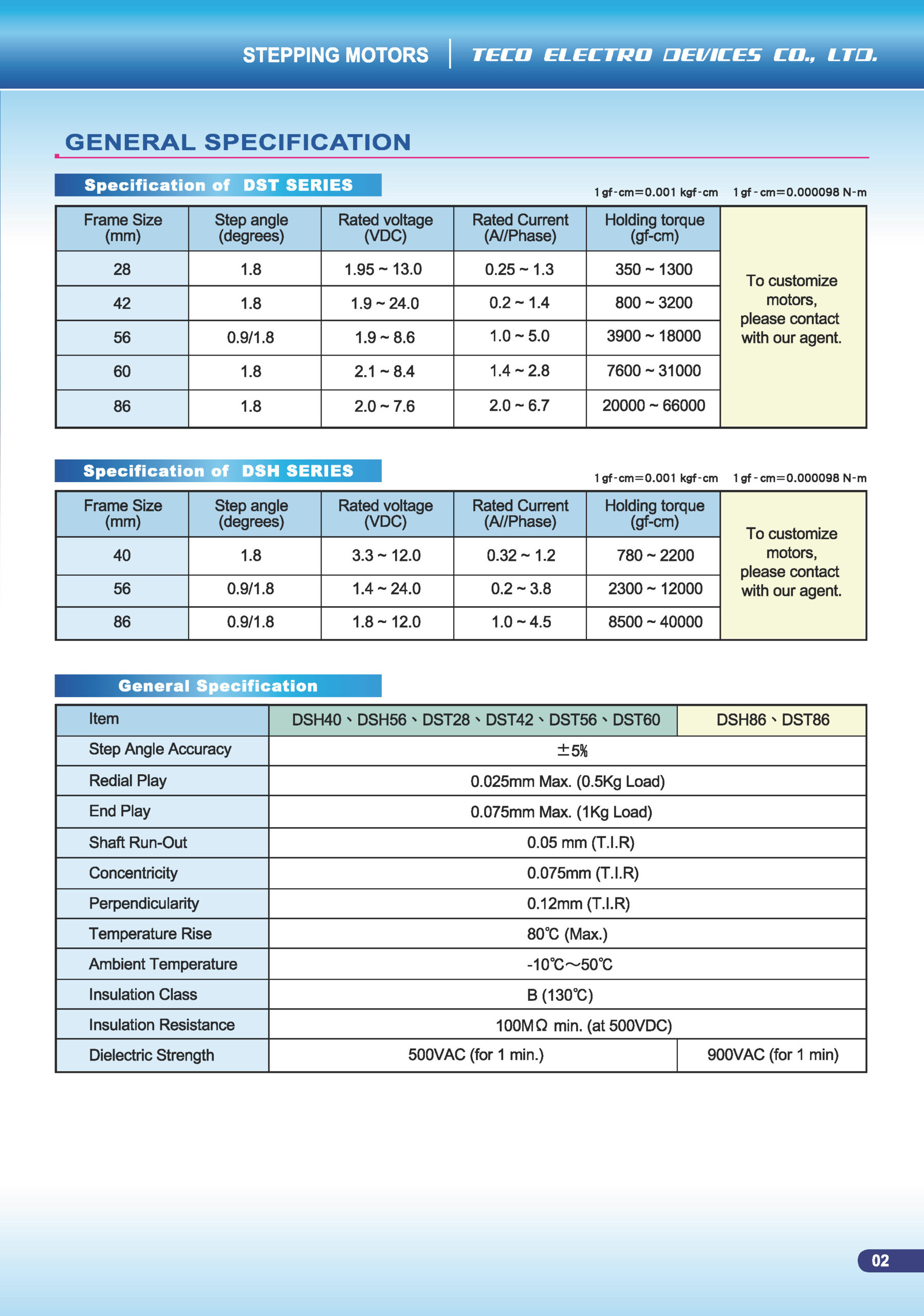

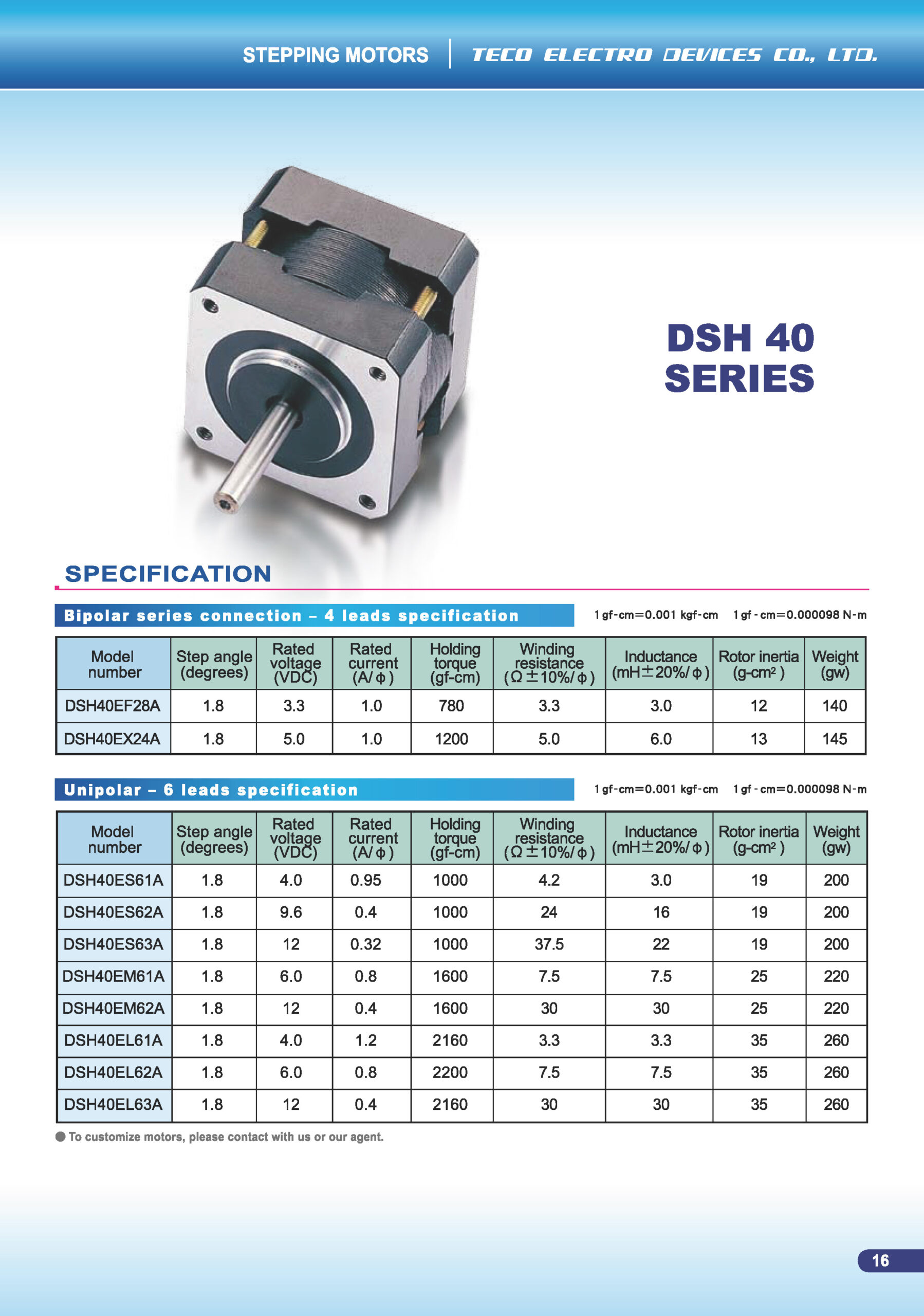

Key Features & Specifications

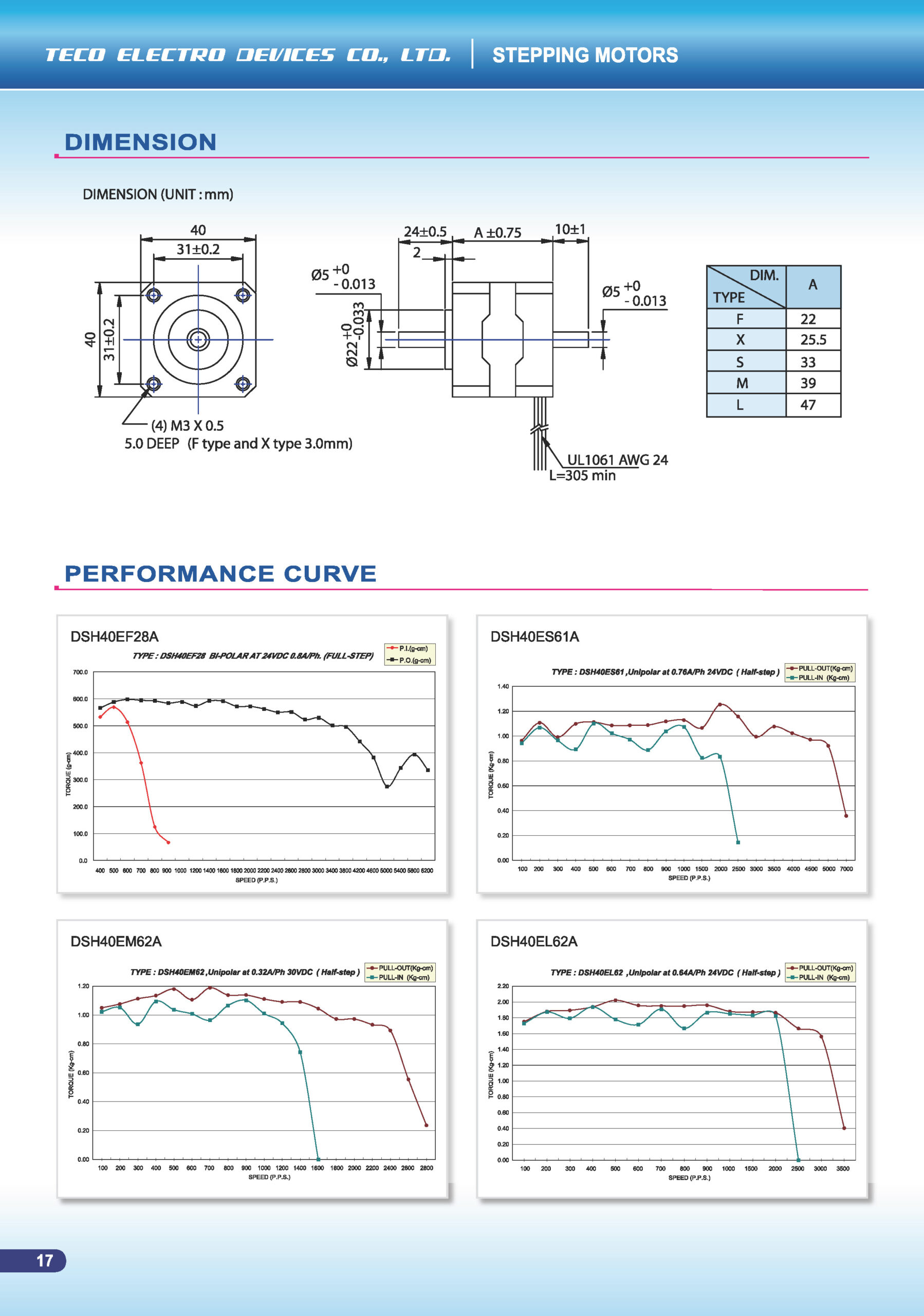

Frame size: Approx. 40 mm body dimension.

Stepper motor type: Two‐phase hybrid stepper motor (standard for this series) with fixed step increments.

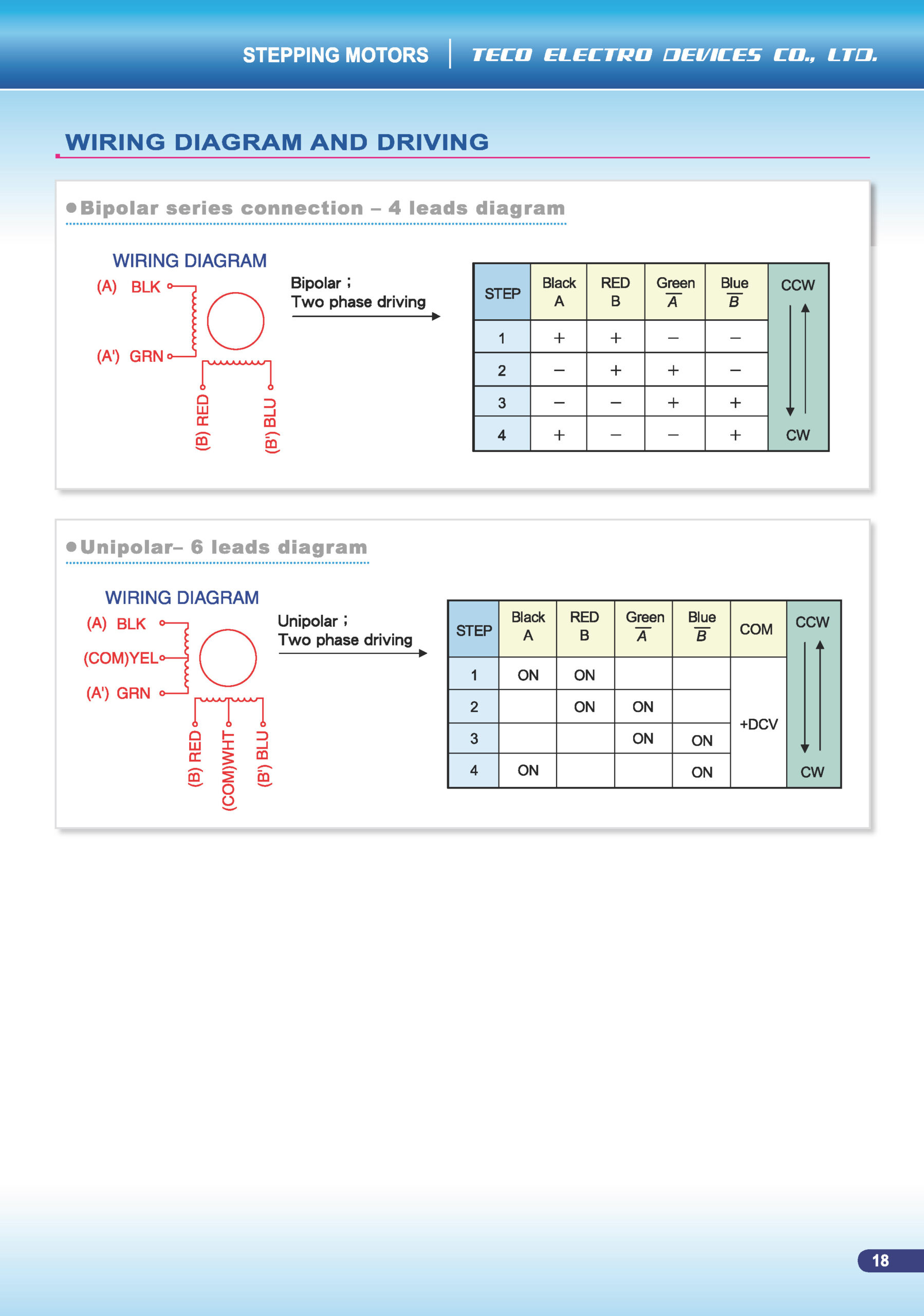

Wiring/lead options:

4‐lead (bipolar) series connection.

6‐lead (unipolar) configuration is also listed for this series.

Typical specification sheet info: The DSH40 catalogue lists winding resistance, inductance, rotor inertia, holding torque, etc.

Mechanical tolerances: The general stepping motor catalogue lists step-angle accuracy (±5%) and radial/end-play limits for these frame sizes.

Typical Applications

Compact automation axes: e.g., feeders, small indexing tables, compact rotary modules.

Light-to-moderate load positioning tasks where a simpler open-loop stepper solution suffices.

Machines or modules with limited space and a cost‐effective motor are preferred.

Design & Selection Considerations

Load matching: Make sure the motor’s rotor inertia and torque capability are well matched to the driven load. A small frame like the DSH40 may struggle if the load is heavy or acceleration demands are high.

Torque vs speed trade-off: As with all stepper motors, torque decreases with increasing speed; consult the specific motor’s torque vs speed curves.

Driver compatibility: Use a driver that supports the motor’s wiring style (4‐lead/6‐lead) and current/voltage ratings.

Open loop vs closed loop: While many stepper applications operate open loop, if missing steps are critical, consider adding feedback or using a servo motor instead.

Mechanical integration: Proper mounting, coupling, and cooling are essential to ensure reliability, especially in smaller‐frame motors.

The DSH40 Series Stepper Motor offers a compact, precision stepping solution for automation applications requiring accurate incremental motion in a small footprint. When properly matched and integrated, it provides a cost‐effective and reliable choice for many machine motion axes.